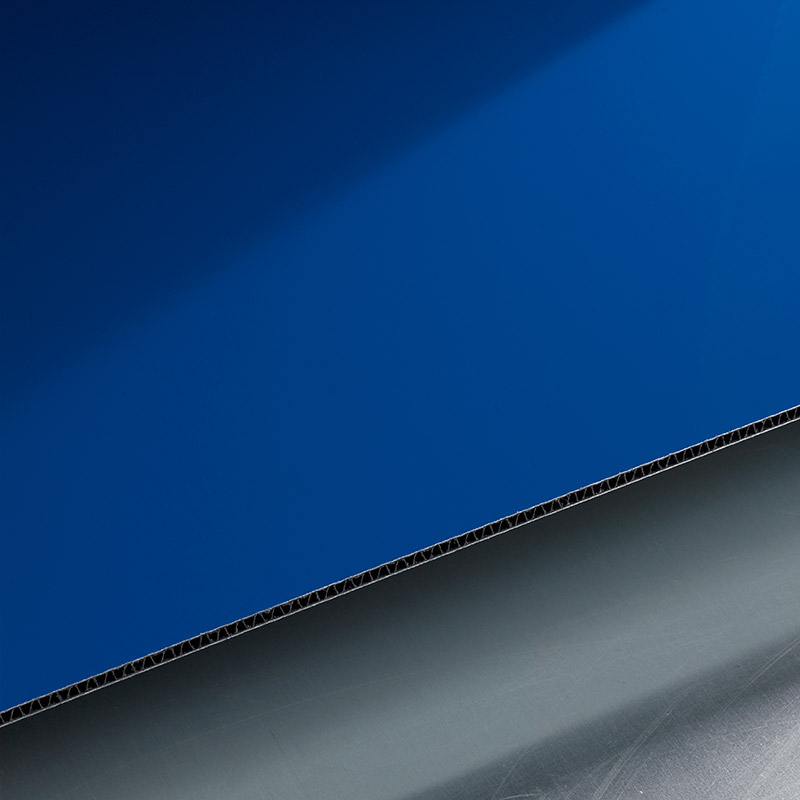

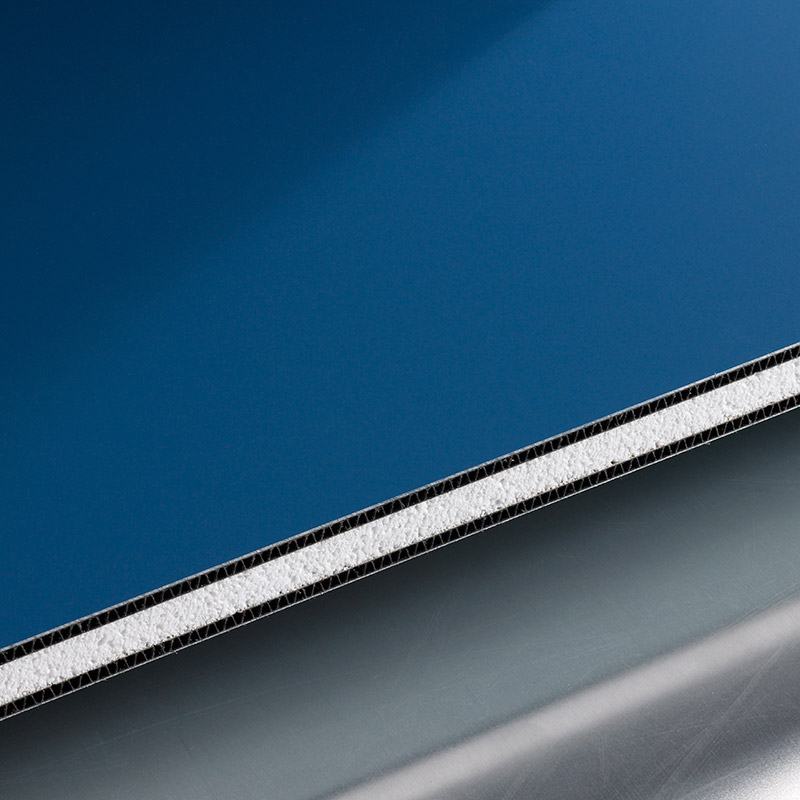

For over 15 years, Laminators Incorporated has been working with cleanroom manufacturers to provide aluminum composite panels that can be used as the wall and ceiling elements in the manufacturers’ designed cleanroom systems. Our ACM panels are comprised of painted aluminum sheets bonded to a high-density corrugated polypropylene core, a solid polyethylene core, or an insulated core making them strong, lightweight, and water-resistant.

The panels have an aluminum sheet bonded to both sides providing excellent rigidity, strength, and durability. The panels will not swell, corrode, rot, wick water, or delaminate—making them perfect for cleanroom applications.

Laminators’ most commonly used panels in cleanroom systems are Alumalite (Standard and Economy), Omega-Bond (Standard, Premium, and Economy), and Thermolite.

ACM Panel Fabrication & Installation

Panels are designed for on-site fabrication using standard carpentry tools allowing clean room assemblies to be designed and installed without costly engineering drawings and shop fabrications. To help save time on fabrication, Laminators can cut panels to your specific project requirements.

Panel Finish

Depending on the panel selected, the finished surface is a high-gloss, factory-baked PVDF/Kynar 500 or a polyester-painted aluminum on two sides that provides a smooth, easy-to-clean finish. The surface is warranted not to crack, chip, flake, or peel. We can also make sheets with a harder PVC skin, rather than aluminum – perfect for cleanroom door and other high-stress areas.

Features & Benefits of Our ACM Panels for Cleanrooms

- Moisture resistant

- Corrosion resistant

- Chemical resistant

- Lightweight

- On-site fabrication

- Class A flame spread

- Alternative to aluminum honeycomb panels

- Double-sided panels for modular/free standing rooms

- V-groove & bend for perfect 90° corners