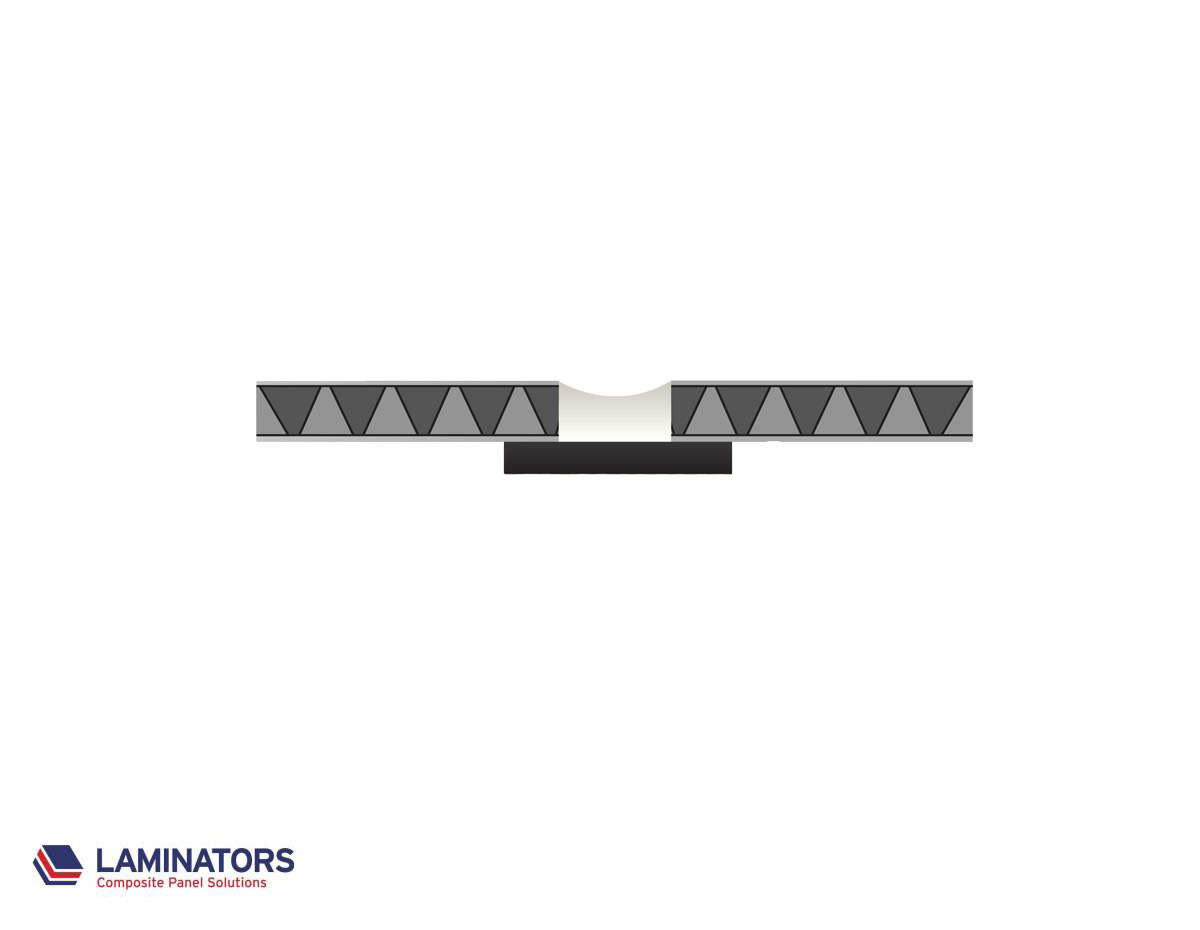

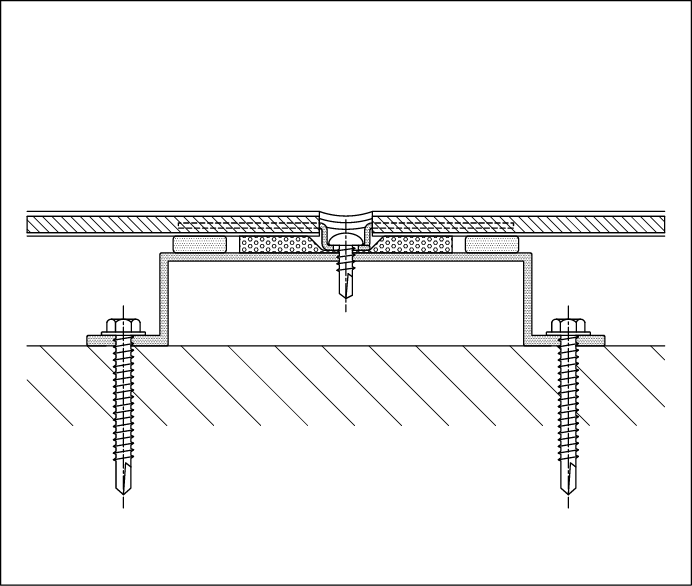

The drained and back-ventilated Clip & Caulk installation system provides the traditional look of a shop-fabricated wet seal system without the added hassle and cost of panel fabrication. The drained and back-ventilated sub-framing provides enhanced system performance through improved moisture management and increased ventilation.

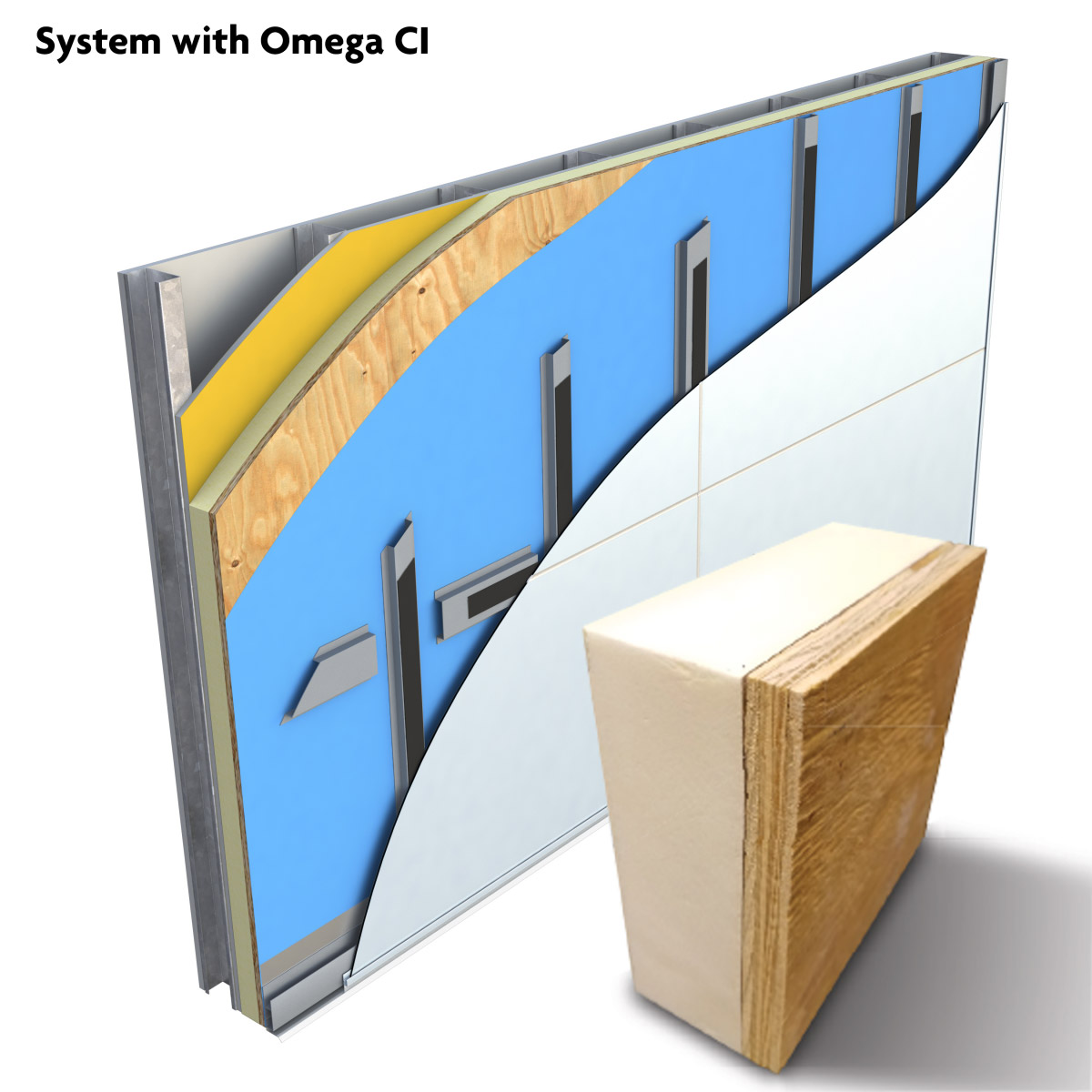

When combined with Omega CI (optional component), the installation system offers an effective solution for veneer installations over continuous insulation while balancing thermal performance, water management, and fire resistance code requirements.

The Clip & Caulk installation system has been successfully tested to the NFPA 285 standard for multi-story fire testing for installations over Omega CI and exterior-grade, glass-mat faced gypsum sheathing.

This economical and easy method is the choice of architects and installers who are looking for a very flat look without visible fasteners. Panels can be cut on-site with few peripheral accessories needed for installation.

Color-matched caulk gives a beautiful monochromatic look; contrasting caulk can be used with eye-pleasing results. Clip & Caulk looks great in combination with masonry, glass, 1-piece extruded molding systems or by itself in a stand-alone application.

RESOURCES

Field-Fabricated Installations Systems Brochure »

Field-Fabricated Panel Systems Specification (1-Piece, Tight-Fit and Clip & Caulk – BDV) »

Continuous Insulation Specification (Omega CI) »

Clip & Caulk™ Technical Data Sheet (BDV) »

Omega CI® Technical Data Sheet »

PORTFOLIO

View Projects Using Clip & Caulk™ Installation Systems

VIDEOS

Drained and Back-Ventilated Clip & Caulk™ Installation System

Omega CI® Rigid Insulation Panel

With outstanding features such as exceptional strength and durability, ease of installation, and the flexibility of custom colors, Omega-Lite is the premier choice in aluminum composite material for a variety of architectural projects across the United States and Canada.

FEATURES / BENEFITS

- Cost effective, yet attractive finish

- Color-matched joint sealants are available

- Fully-integrated, high-performing wall system

- Easy solutions to code conflicts (NFPA 285, Continuous Insulation) – NFPA 285 compliant for multi-story buildings*

- Eliminates complex detailing associated with most proprietary solutions

- Faster finished wall assembly with reliable scheduling

- Panel installation time is greatly reduced because Omega-Lite® can be erected immediately after the sheathing crew has finished prepping the wall

- Omega-Lite systems install directly to Omega CI’s plywood sheathing (Omega CI is optional) – removes complex detailing and extensive planning associated with most proprietary solutions for installation of ACM veneer systems over continuous insulation

- Sub-framing components can easily be adjusted during construction providing installers with the flexibility necessary for a successful installation

- Versatile – Omega-Lite panels offer a highly decorative, strong, and durable surface finish for exterior wall surfaces

- Gives designers and installers the freedom to choose any air and water barrier product that can be installed over plywood sheathing (NFPA 285 requirements were met using Barritech VP)

- Virtually all system components are available from Laminators Inc., making us your one-stop shop

- Laminators Incorporated maintains an ICC-ES Listing Report the Clip & Caulk with Drained and Back-Ventilated (DBV) over both Omega CI and gypsum sheathing

*Refer to NFPA 285 compliant CAD drawings

Need a quick budget number but can’t wait for a take-off? Let us help!

Submit our Budget Pricing Request Form and we’ll provide you with estimated quantities and budget numbers for your upcoming project.